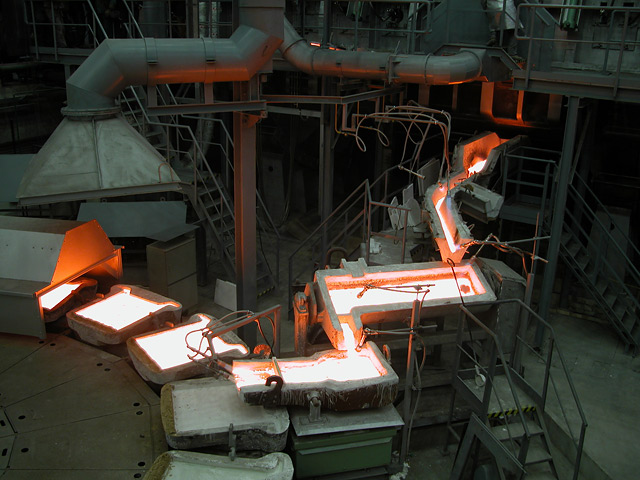

Copper Anodes

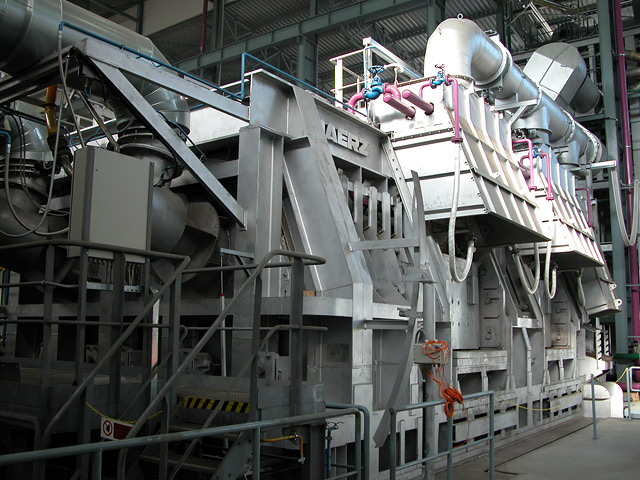

The description of the anode furnace production

After charging of the copper material into the furnace starts the process of smelting and after whole mass meltdown the process is followed by the oxidation to achieve the unwanted impurities removal. When the impurities are removed follows the slag removal and phase of reduction with natural gas. Reduction is aimed to remove the free oxygen. After the reduction the process is ended by casting, where the final product is casted into the form of copper anodes.