Pyrometallurgy

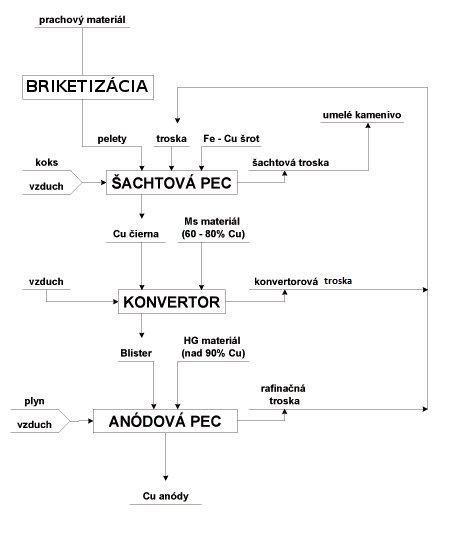

Process of pyrometallurgy is running in 3 production aggregates - Shaft furnace (ŠP), Converters and Anode furnace.

By pyrometallurgy are processed materials with copper content from 5% up to 99% of Cu. In dependence on copper content and granulometry are these materials processed individually on production aggregates as follows - shaft furnace 5-60% Cu, converters 60 - 85% Cu, and anode furnace above 90% Cu. For the modification of copper dust material is used pelletization disk and the output is a dust material rolled up to firm pellets.

Shaft furnace - in here is running reduction smelting of Cu materials, as a fuel is used coke and the outcome of smelting is black copper (70 - 75% Cu) and shaft slag - artificial stone for building works.

Converter - is processing the product of shaft furnace smelting - Cu black with the addition of materials with Cu content of 60 -85%. The result of oxidation process is a blister copper with content of 95 -96% of Cu.

Anode furnace MAERZ - the furnace is the heart of the new modern line for the production of Cu anodes. Processed is the material with Cu content above 90% and blister from the own converter production, the output are the copper anodes as a final product for commercial use.

In year 2008 company has finished construction and brought to test operation "line for the Cu anodes production". With this investment will be reached the rise in production to 50 000 t of anodes per annum, the cut-down on costs for the produced ton and also environment impacts. The line consists from refining furnace MAERZ, casting mechanism OUTOKUMPU with precise casting of anodes and maximum anomaly in weight 0,5 kg, afterburning chamber for CO, exhaust-heat boiler for the steam production and filtration mechanism for off-gases and fugitive emissions. This year is also prepared investment which will help to change the produced steam on electrical power used back in production process.